a Constructing compound Exciter circuit

Fig.4 Magnetizing characteristic curve for wire rope

Independent single piece of wire rope testing can acquire the satisfactory results with choosing the permanent magnets of the proper number, utilizing the fork form pole terminal, according to the structure of the wire rope, or adopting single of multi circuit excitation in the radial direction. As shown Fig 4. With regard to 6×19 round strand wire rope of structure, at that time, the intensity of magnetization for the wire rope is 3-4×103 A/M. So long as you try to make it at the moment when the wire rope passing through the sensor to attain the magnetizing approaching saturated zone, you can get the satisfactory result. According to experience we know the permanent magnets in the sensor would provide enough intensity exciting field and can make the intercity of magnetization attaining 4~5×103 A/M concentrically in the wire rope testing for electrical elevator. There fore, adopt magnets paralleling, circumference equal distribution, multipoint polar pillar installation, thus form compound exciting, circuit. The polar pillar arrangement of magnets must be avoided, the closing of magnetic line, interfere and other slight effect, for the vector-orient ability and non-linearity.

b.Constructing magnetic shielding can conform the diffuse magnetic field near the wire rope.

After the intensity of magnetization in wire rope measured acquire the focus, the another wire rope would still be synchronized magnetization by the diffuse magnetic field for the sensor right next another wire rope. There fore we adopt the functional high permeability materials to construct magnetic shielding on the surface of the sensor. Resist the magnetic line entering non-working areas.

4. RTS the application for the electrical elevator wire rope testing and diagnosing system

4..1 The structure of sensor

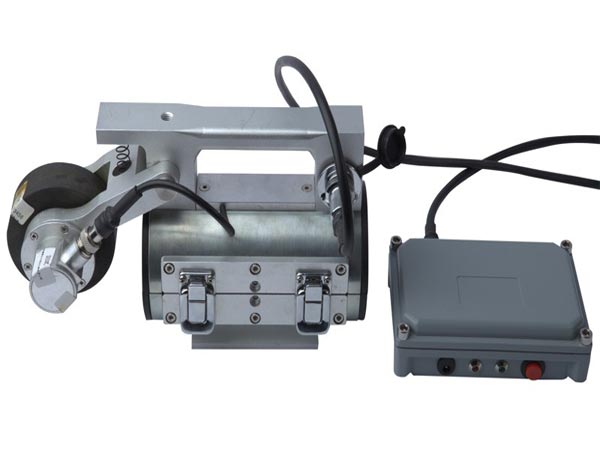

Fig.5 sensor structure diagram

As shown Fig.5, ① Location Encoder ②Sensor mandrel ③Main Fixed Support ④Sub-fixed support According to the different diameter wire rope measured for electrical elevator, can change ②the sensor mandrel for attaining accurate qualitative quantitative testing results. If the dragger circumstance location in elevator machine room is limited, use the upper part of the half sensor can acquire the same satisfactory results. But the accurate rate of the broken wire quantitative testing would decrease about5%.

4.2 Working in site

Fig.6 Elevator wire rope testing worksite

As shown Fig.6, all we need do is two inspectors, and can achieve the whole work in the dragger machine room promptly. One of them hold the sensor in his hand, the other operate the computer sampling, bear responsibility for the initiation and stop of electrical elevator wire rope and take notice of worksite safety.

4.3 Computer software

So long as you can operate the TV, on the basis of the interface prompting can conduct operation. To calibrate only once for every type wire ropes can transfer under a unified plan for a long time.

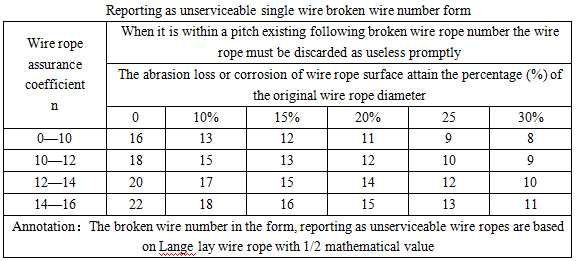

To show the broken wire location of the wire ropes, quantity and according to the broken wire quantity with in the length of lay pitch of the state current standard stipulation directly.

In this interface, you can confirm broken wire accurate quantity of the wire ropes and the flaw of the corrosion, loose ply, trans shape, material quality changes etc.

The data of the right column show the percentage numerical value of the change of the metallic cross-sectional area in the wire ropes. The waves show the manufacturing quality and other flaw.

5. The Application Direction Discussion for Electrical Elevator

Because of the technique and idea lagging, the elevator wire rope testing has taken over the traditional methods of artificial visualization. With the development of technique and the progress of the people’s idea, every enterprise authenticates from quality management ISO9000 and environmental management 14000 to professional safe health OHSAS18000. Management begin (and even more some of them have stipulated) stipulate that the wire rope testing must apply scientific instrument. Up-to-date Ordeas Gen2 Elevator form plastics and steel composite belt promotion out of 12 pieces of wire ropes. It should be said. It is no problems for safety absolutely. But every elevator without exception dispose the safty testing instrument of a suite of plastics and steel composite belt for the wire rope core. Thus it can be seen magnificent prospects in the application and popularization respect for RTS elevator wire ropes testing instrument.

Elevator supply and Maintenance: Advance notability enterprises can heighten qualitative grade. Backward notability enterprises can expand the occupation ratio of the market.

Architectural Real Estate Management: Relieve having anxiety over possible danger from behind of proprietors and passengers. Alleviate their psychological burden when the passengers take the.

Reference Literature:

1.Dong Xinhua Kang Yihua “Quantitative Inspection technique on line for the wire ropes” 1999

2.Beijing Labour and social Security Bureau “Supervisory Document Compilation for Labour Protection” 1997—1999

3.Ordeas elevator Company “Innovation Science and Technique for Architectural Trade” 2000